Coriolis Mass Flow Meters

for Liquid and Gas

3/8" to 10"

Regular price

$7,300.00

Sale

Coriolis flow meters (also referred to as Coriolis mass flow controllers) are very accurate flow meters designed to measure the flow rate of liquids, slurries, & oils. Our flow meters ship from stock (usually within 48hrs) and are configured for you to be plug and play. They feature a very easy to use user interface with "Thru the Glass" technology.

A Coriolis flow meter contains a tube which is energized by a fixed vibration. When a fluid (gas or liquid) passes through this tube the mass flow momentum will cause a change in the tube vibration, the tube will twist resulting in a phase shift. This phase shift can be measured & a linear output derived proportional to flow.

Our EASY to use CORIOLIS Mass Flow Meters are in stock at prices that beat our competition.

Display

Features LARGE OLED display, shows the Instantaneous (Instant) Flow Rate, Total Flow, Temperature, and Density in user selectable units.

Manual

Specifications Model Number

MODEL NUMBER SYSTEM:Note: Click image to open the PDF of the Model Number system below.

Coriolis_Mass_Flow_Meter_Model_Number_for_Custom_Meters

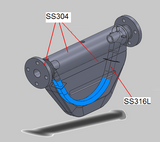

- Sensor Wetted Materials 316 SS Standard

- Flanges and flow splitter Materials 304 SS Standard

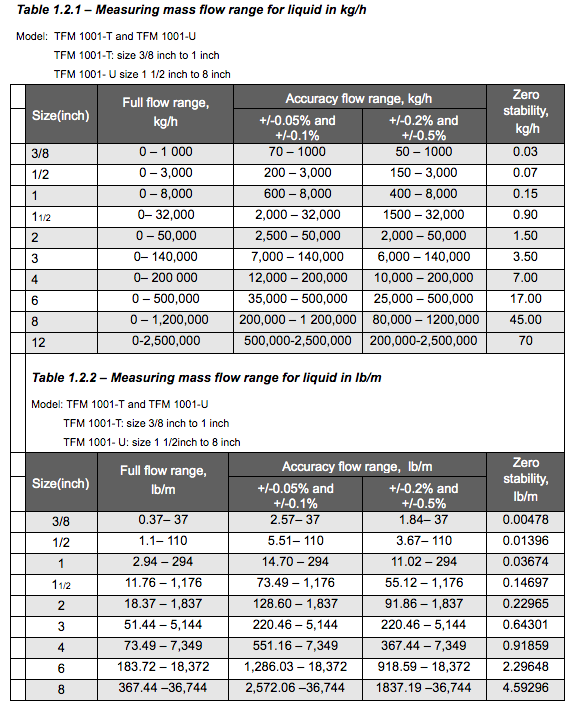

- Flows from 0.1 kg/h to 1,000,000 kg/h relative to water

- Accuracy: +/- 0.2% or 0.5% of reading in gas or water. 0.1% available on special order. Note: turndown typically 20:1

- Repeatability of +/- 0.02% of reading

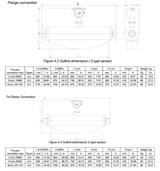

- 3/8" to 8" 150# ANSI Flange Connections, up to 12" available custom as well as 1/4" Swage to 3/4" Swage and TriClover Sanitary fittings.

- OLED Display

- Temperature Accuracy +/- 1 Deg C

- Temperature:

- Gas: -58°F (-50°C) to 257°F (125°C)

- Ambient: -40°F (-40°C) to 131°F (55°C)

- Power Requirement: 24 VDC or 85-220 VAC, 15 Watts maximum;

- Output signals: Modbus RTU, 4–20 mA, and 0-10 KHz for flow rate indication

- Digital communications: Modbus RTU Standard, HART Optional

- Proof Pressure 4.0 MPa, 580 PSIG, Up to 25 MPa (3,600 PSIG) available.

- Display: Flow rate, Total flow, Temperature, and Density

- Wiring connection to enclosure size: M20 x 1.5 or NPT Optionally available.

- Integral Electronics installation

- Explosion Proof Rating: UL/CSA Class 1 Div 1 standard.

- Electronics Enclosure NEMA 4X / IP67

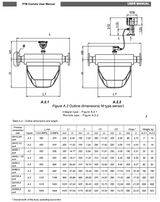

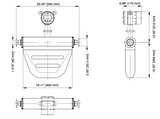

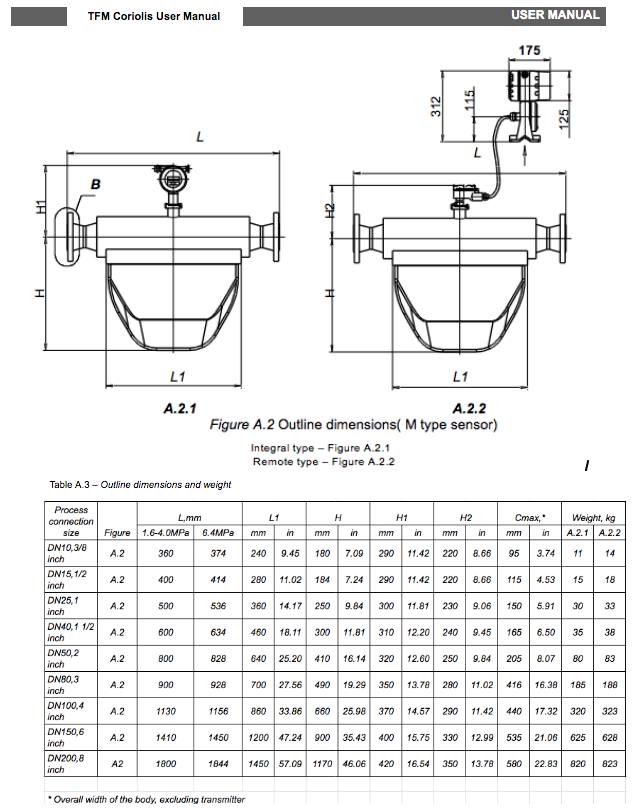

Dimensions

Types T and U

Types T and U

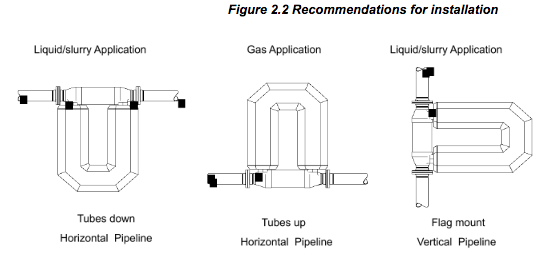

Mounting Guide:

Programing Menu

Click to enjoy a LARGE size of the menu in PDF shown below.

Zero Calibration

Notes about ZERO Calibration on Coriolis meters.

NOTE: It is critical to invoke the zero point calibration after installation.

Every Coriolis Meter must be zeroed in the final installation point with the fluid that will be measured. Make sure the meter has warmed up for at least 15 minutes before invoking the zero function. Make sure the measuring tube is fully filled with liquid. Turn off the stop valves, make sure the liquid is in a stationary state, and invoke calibrate the zero point as shown below. The zero function is in process when the display indicates "Zeroing, please wait for 30 s" for about 30 seconds and then reverts to the zero uS display mode. This function is CRITICAL to allow the meter to determine the resonant frequency of the measuring tube is to determine the density of the fluid within it. This step cannot be skipped. Once this step is complete you will want to confirm the measured density is accurate. Coriolis mass flow meters directly measure the mass flow and the density of the fluid. The volume flow rate is calculated by mass flow divided by density. If the density measured at the zero point is not accurate, then the flow rates will be affected as well. We explain what is shown in the manual below for ease of access.

- Using the root menu (see Figure 2.14) press ↓ button several times to move to the Menu item “Configuration Press E to enter”. Press E button and enter the password (default password is 000000). To enter the password press ↓ to increment the currently selected digit, to move to the next digit press → button. After correct password entry The screen will say Flow Config Press E to enter. Press E. Next the screen will say Zero Calibration with the zero uS below. Press E to start. The Zeroing message will appear with a blinking N. Use the → to make the Y blink. Press E to start zero calibration procedure. A message “Zeroing?” will appear. Press E to confirm that. Zero calibration procedure lasts for 30 seconds, the count down time is displayed.

- NOTE: Multiple hits of the Center Button gets you OUT of the menu structure.

Where to get Power Supplies, Gaskets, Nuts and Bolts Link

Coriolis Wiring Validation

All flow meters require that the fluid delivered is free of gas bubbles. The TFM-9005 Gas Eliminator is one way to address this need. Frequently used in oil fields as well as other processes that have entrained gases.

TFM-F9005 Gas Eliminator and Strainer Cut Sheet, Download here